1️⃣Gas Spring Selection Knowledge Center

Welcome to the DampFlex Gas Spring Knowledge Center.

At DampFlex, we specialize in high-quality automotive and industrial gas springs, providing reliable solutions for your applications.

Our goal is to help engineers, designers, and technical buyers select the right gas spring for every project—whether it’s for precise force, correct dimensions, optimal rod diameter, or proper mounting.

Explore our guides and technical insights to ensure safety, performance, and long service life for your systems.

2️⃣Gas Spring Basics

A gas spring is a mechanical device that uses compressed gas to provide a controlled force for lifting, lowering, or positioning applications.

Key parameters of a gas spring include:

– Force (N): the pushing or lifting strength

– Extended Length (EL): the total length of the gas spring when fully extended

– Stroke: the distance the rod travels during compression

– Rod Diameter: affects stability and load capacity

– Tube Diameter: affects internal pressure and durability

Understanding these basics is essential for selecting the right gas spring for your application.

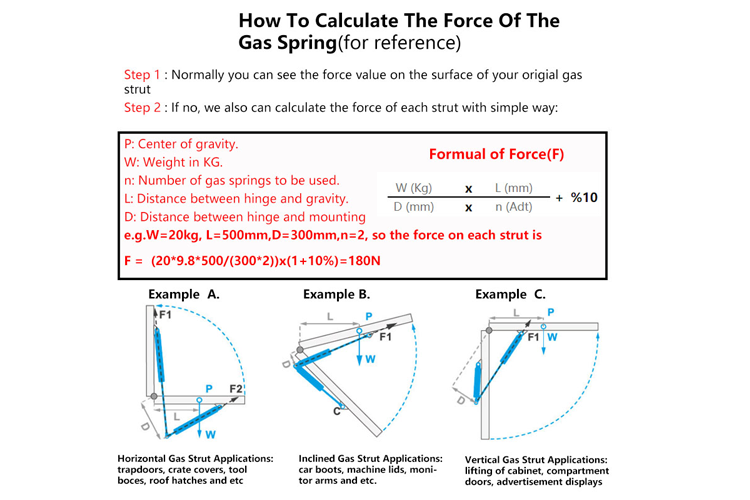

How to Choose the Right Force

How to Choose the Right Force

Selecting the correct force is critical to ensure proper operation and safety.

The required force depends on:

– Load weight: the weight of the lid, door, or panel

– Geometry: the angle and pivot point of the mounting

– Safety factor: to compensate for wear, temperature, and user operation

A gas spring with insufficient force will fail to lift or hold the load, while an oversized force may damage components or pose a safety risk.

How to Choose the Correct Size

How to Choose the Correct Size

Gas spring size is defined by two main parameters:

– Extended Length (EL): the length from mounting hole center to mouting hole center when fully extended , not total length from end point to end point

– Stroke: the travel distance of the rod

Compressed Length = EL – Stroke

Proper size selection ensures the mechanism opens and closes smoothly without over-compressing or over-extending the gas spring.

5️⃣ How to Choose Rod Diameter

Rod diameter affects stability, side-load tolerance, and service life.

– Small diameter (6–8 mm): light applications, short stroke

– Medium diameter (8–10 mm): automotive hoods, trunk lids

– Large diameter (10–12 mm): heavy industrial applications

Always consider the mounting orientation, cycle frequency, and load type when selecting rod diameter.

6️⃣ End Fittings & Mounting

Choosing the correct end fittings and installation method is essential for safe and long-lasting operation.

Common fittings include:

– Ball joint

– Eyelet

– Clevis

– Bracket mounting

Key points:

– Rod down orientation is generally recommended

– Avoid side loads

– Allow for correct pivot angles

Proper mounting prevents binding, excessive wear, and potential failure.

7️⃣ Application Scenarios

Automotive:

– Hood

– Tailgate

– Trunk

Industrial:

– Enclosures

– Machine covers

– Toolboxes

Furniture:

– Cabinet doors

– Bed lifts

8️⃣ Common Mistakes

– Selecting force without considering EL and stroke

– Ignoring temperature effects

– Incorrect rod diameter for application load

– Using wrong end fittings or mounting orientation

– Replacing gas springs without recalculating specifications

9️⃣ FAQ

Q: Can I replace a single gas spring only?

A: Yes, but ensure the replacement matches the force and size specifications of the paired spring.

Q: What happens if the force is too high?

A: It may damage the lid, hinge, or surrounding components and pose safety risks.

Q: How do I calculate force for a new application?

A: Measure load, pivot point, and angle. Use the formula: Required Force = Load × Geometry Factor × Safety Factor.

Q: Can I customize gas spring force or size?

A: Yes, DampFlex provides custom solutions based on your technical requirements.

🔟 Need Assistance Selecting the Right Gas Spring?

Our engineering team is ready to help you select the ideal gas spring for your application.

Provide your application details and we’ll guide you to the optimal solution.